Client: ConfidentialEngineer: Format Engineers LtdLocation: West England, UK

Date: 2019-02-01 00:00:00 +0000 UTCTags: bridge, steel, computation

Wessex Walkway

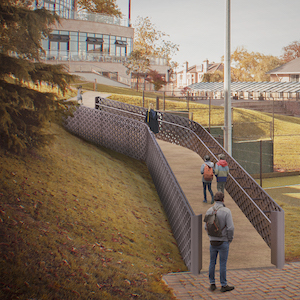

Format Engineers were invited by a private school in the west of England to plan and design a new bridge link across very different levels on their sprawling campus site. The new link brings a poorly used recreation area into wider use and improves access between facilities. It has also been designed to double as a viewing platform over the school’s sports pitches. The 25m long pedestrian bridge, despite its high quality materials and curved form, is one of the least expensive structures of its type quoted by a well known steel fabricator.

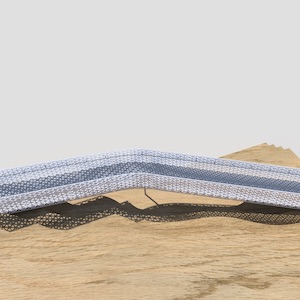

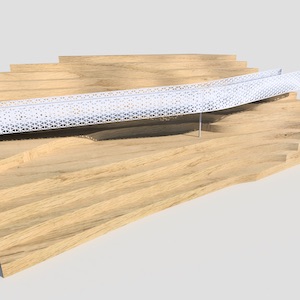

We were able to limit the cost by eliminating manual labour in the fabrication process. Welding was almost entirely avoided by adopting a press fit bolted system and the parapet was formed with a water jet cut stainless steel plate. This removed the need for a paint application, a multitude of fixings in the parapet and costly long term maintenance.

The form of the bridge is that of a snaking S curve which makes maximum use of the site area to descend at a DDA compliant gradient. The plan shape is then tweaked with goal seeking algorithm in a computer based script to make the frame as lean as possible. To reduce the material in the deck further the parapet is utilised as part of the structure with the bends in the plan form stiffening the plates against buckling. The parapet is lightened in weight and visual appearance by water jet cutting a triangulated void pattern in the parapet plates. The pattern is informed by the distribution of stress in the plates. The Wessex Walkway can be said to be a rigorous exercise in material saving whilst retaining a high visual quality.