Client: WSP UK/Network RailStructural Engineer: Format Engineers/WSP UKLocation: Wokingham, United Kingdom

Date: 2024-11-01 00:00:00 +0000 UTCTags: Steel, Repurposed, Bridge, Digital Design, Parametric Design, CNC

Tan House Crossing

Tan House footbridge was a collaboration between Network Rail, WSP UK and Format Engineers. The use of repurposed steel has been the centre point of the design process and has been possible through the use of creative digital techniques that facilitated a refinement of the typology to match the available stock of old steel. The use of generative digital methods permitted an iterative and flexible design process that allowed material and embodied carbon savings flowing from different options to be tracked each step of the way towards fabrication. Our collaborative work is a good illustration of the need for global carbon reduction to be led by early design decisions.

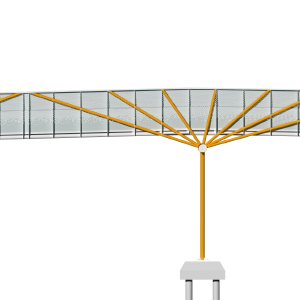

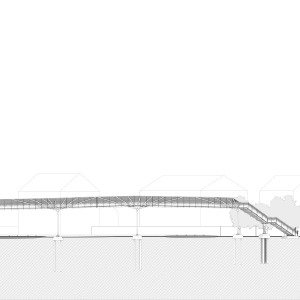

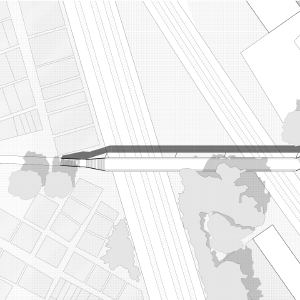

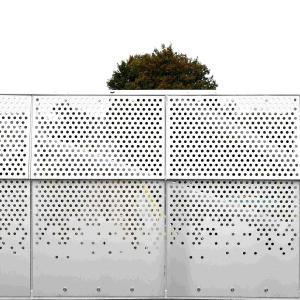

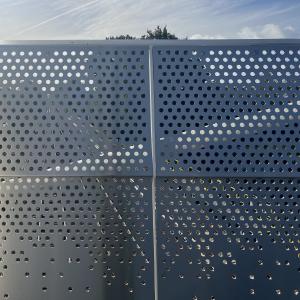

The new structure is an elevated deck composed of three spans of 18.4, 15.4 and 19.5m and is made accessible by stairs at each end. The elevation is a minimum of 5.5m above the tracks, a clearance to allow the possibility of future OLE on both lines. Stairs were designed to be removed and replaced with ramps at a later date. In line with Network Rail design standards the parapet is 1.8m tall. The brief from the client was sufficient porosity through the parapet to allow views out from the bridge but sufficiently opaque to give a sense of protection over the elevated height. A solid ‘kick plate’ of 600mm high is incorporated within the parapet. The bridge deck is of 3.1m clear width, an unusual dimension due to the section profile of the bridge being constrained by the intention to deliver the large prefabricated sections of the bridge to the site by rail under an existing low and narrow bridge. The considerable depth of the parapet and the need to avoid elevating the bridge deck too far over the minimum headroom restriction (and thus avoid a longer access stair or ramp) led to the decision to fit primary structure within the parapet. Primary radiating fans of CHS sections which nearly meet at mid-span were determined after a conceptual design process. The parapet splays outwards in section to give a generous feeling of space. The fan structure meant that the top chord could be deliberately kept small in profile and thus avoid being a visual distraction at human head height. The structure is a half-through bridge with laser-cut steel plate U-frames at regular intervals to stiffen laterally the top parapet structure and hence control the lateral-torsional mode.

At the time of writing the writers believe Tan House to be the lowest embodied energy footbridge Network Rail have constructed on a live site. Tan House is considerably lower in CO2 than the standard series 400 steel rail bridge and is a testament to the fact that a bespoke and site-appropriate design does not have to be costly in capital expenditure or embodied energy.

Tan House footbridge is a great example of how the design to minimise embodied energy can inform the typology of a structure and not just its material or the size of its cross sections.Finally Tan House illustrates how low cost public infrastructure works can be delivered with a bespoke solution and one which is absolutely suited to the site rather than a standard design being imported from elsewhere.

| Bridge owner and client: | Network Rail |

| Lead Designer: | WSP |

| Bridge and stair Designer: | Format Engineers |

| Cat 2 check: | WSP |

| Principle Contractor: | Balfour Beatty |

| Structural Steel Contractor: | SH Structures/Allerton Steel/NU Steel |

| Repurposed Steel Supplier: | Cleveland Steel |

Images: 7 - Wokingham Aerial Photography, 8,9,10,12 - Network Rail, all others Format Engineers Ltd